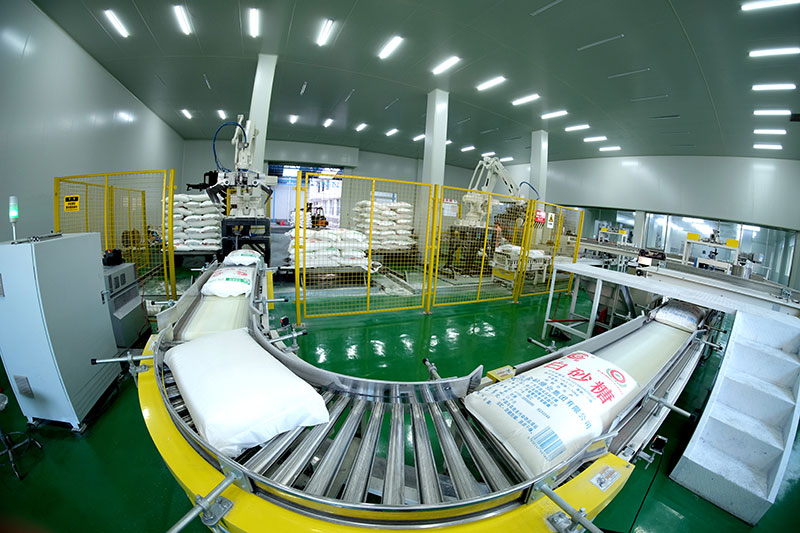

Fully Automatic Robot Production Line of Packing and Palletizing

The Fully automatic robot production line of packing and palletizing researched and developed by GRI can be used for automatic packing of powder and granular materials in the sugar, food, feed, fertilizer, starch, chemical, pharmaceutical and nano-calcium carbonate and other industries. The inside bag is sealed by the high temperature, and put into the outside bag, then the outside bag is automatically sewn. The pack is completely sealed without a needle eye, which is the world's first.

The application in sugar factory

The production line has the characteristics of strong flexibility, high degree of automation, small footprint, and low cost of use compared to composite bags. It is a major project supported by innovation and development in Guangxi. It has won 8 patents, including 1 patent for invention. Now it has been successfully applied in Guangxi Yangpu Nanhua Sugar Industry Group Co., LTD, Yongxinhuatang Group Co., LTD, Guangdong Jinling Group and other companies, and has been widely praised by customers.

Specification parameter

|

product model |

NWDZ-3 |

|

Applicable material |

white sugar, feed, fertilizer and other granulated and powdered materials |

|

Bag form |

Detachable two-layer bag(the inner bag is longer than the outer bag 100±10mm) |

|

the size of woven bags(L×W) |

(550~1120)×(200~750)mm |

|

packing speed |

6-8bags/min |

|

packing weight |

20-50kg/bag |

|

power supply |

AC380V±10% 50Hz±0.5HZ(Three-phase five-wire ) |

|

pressure of air |

≥5kg/cm2 |

|

ambient temperature |

1-28℃(Install refrigeration air conditioner) |

|

relative humidity |

<80%(Install refrigeration air-conditioning to ensure that the environment is relatively dry) |

|

power |

25KW |

|

water supply |

Provide water for sugar powder collection |

|

boundary dimension (mm) |

300*320*390 |